Watererstops hydrophobes en polymère (fabriqués en Chine)

Informations de base

Modèle: various

Description du produit

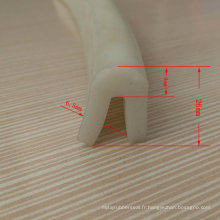

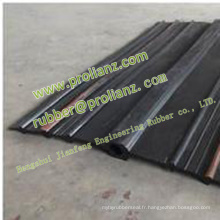

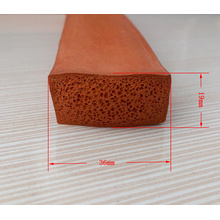

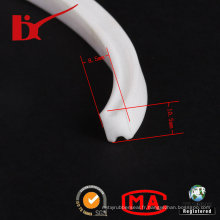

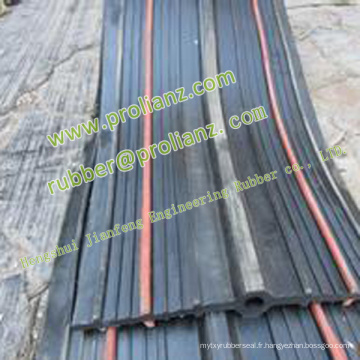

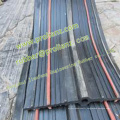

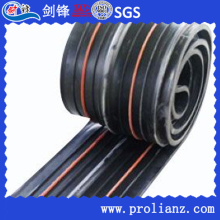

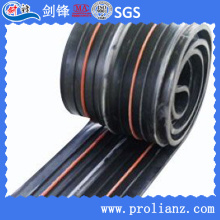

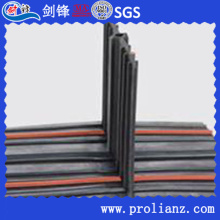

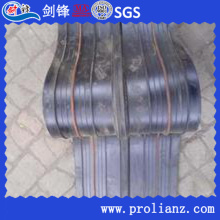

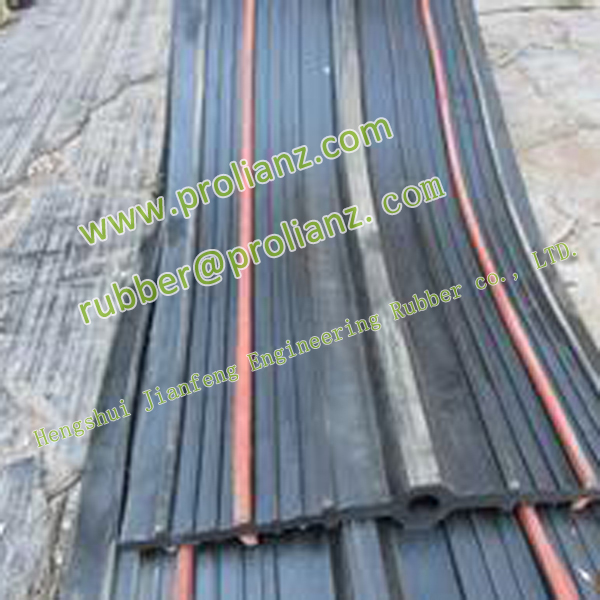

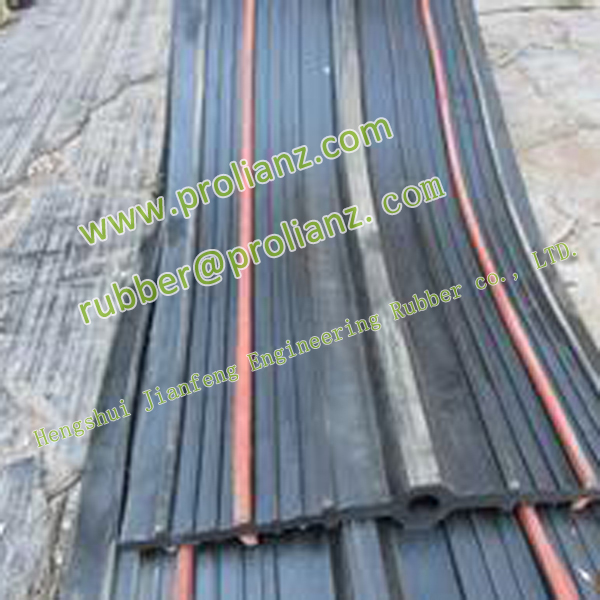

N ° de modèle: diverses forme de carreaux de plafond: rectangle épaisseur: 3.0mm traitement de surface: rouleau enduit Certification: ISO utilisation: certificat de joint en béton: ISO9000 commande urgente: oui emballage de transport: dans des palettes ou des cas en bois origine: Hebei, Chine Matériel matériel: Tuile de plafond de HDPE Type: Caoutchouc Fonction: Étanche Couleur: Noir Marchés d'exportation: Global Szie: Standard ou adapté aux besoins du client Marque déposée: JianFeng Spécifications: Comme demandes de dessin Code de SH: 522338 Coordonnées \ nGérant de vente: kent \ n 15233296877 \ nTel: 86-318-5106277 \ nFax: 86-0318-5106277 \ nSite Web: www.prolianz.com \ nEntreprise: Hengshui Jianfeng Engineering Rubber co., LTD. \ n  \ n \ nIntroduction de l'arrêt d'eau hydrophile

\ n \ nIntroduction de l'arrêt d'eau hydrophile

\ n \ nCaractéristiques de l'arrêt d'eau hydrophile

\ n \ nCaractéristiques de l'arrêt d'eau hydrophile

\ n \ n \ n Propriétés physiques de l'arrêt de l'eau hydrophile

\ n \ n \ n Propriétés physiques de l'arrêt de l'eau hydrophile

\ n \ nIntroduction de l'arrêt d'eau hydrophile

\ n \ nIntroduction de l'arrêt d'eau hydrophile | Hydrophilic water stop is made from water-swelling rubber water line to the basis of the ordinary rubber waterstop. The product will swell when contacted with the structures. As a result, the tightness is fastened between the water stop and water-proof performance is improved and the problem of circle seepage which puzzles people in a long time is solved. This series of products have been used widely in some key projects and have gotten excellent results. |

\ n \ nCaractéristiques de l'arrêt d'eau hydrophile

\ n \ nCaractéristiques de l'arrêt d'eau hydrophile | Waterproof wire adopted water-swelling rubber which will be self-swelling when contacted with water. So under the function of waterproof wire ,the concrete and water can seal better, and waterproof performance can be more excellent.The sections divided into high-strength area, water-proof area and the installation area can take unequal thickness structures according to the unique function of every area. So each part of the sections can get uniform and reasonable force.Telescopic holes' outer wall is plane; formwork folder system contact surface is large in construction and difficult to dislocation.Setting hole designed on the installation area is convenient to fix with the nearest steel bar, difficult to move , construction easily and install firmly. |

| Rubber water-stop bailey, mainly is suitable for the deformation seam in B; Suitable for construction joints with water stop, S; Apply to have special aging resistant requirements of seams with water stop with J said. Welcome the masses of customers to use our company's series rubber water-stop effect and principle of rubber water-stop product quality achieved GB18173.2-2000 requirements of the buried in the type of rubber water-stop back rubber water-stop is using rubber high elasticity and the characteristics of compression deformation, elastic deformation under various load, thereby a fastening sealing, prevent the leakage, seepage and shock absorption effect of structures. |

\ n \ n \ n Propriétés physiques de l'arrêt de l'eau hydrophile

\ n \ n \ n Propriétés physiques de l'arrêt de l'eau hydrophile | Description | Index | ||||||

| B | S | J | Swellable strip | ||||

| 1. Hardness ( Shore ) | 60±5 | 60±5 | 60±5 | 42±7 | |||

| 2.Tensile strength ,Mpa ≥ | 15 | 12 | 10 | 3.5 | |||

| 3.Elongation at break , % ≥ | 380 | 380 | 300 | 450 | |||

| 4.Compression set % | 70ºC×24h ≤ | 35 | 35 | 35 | --------- | ||

| 23ºC×168h ≤ | 20 | 20 | 20 | ||||

| 5. Tear strength ,KN/m ≥ | 30 | 25 | 25 | ---------- | |||

| 6.Brittleness temperature , ºC ≤ | -45 | -40 | -40 | ----------- | |||

| 7.Hot air aging | 70ºC×168h | Hardness (shore) | +8 | ------ | - | ---- | |

| Tensile strength ,Mpa ≥ | 12 | ------- | - | ||||

| Elongation at break, % ≥ | 300 | -- | - | ||||

| 100ºC×168h | Hardness (shore) | -- | -- | +8 | |||

| Tensile strength ,Mpa ≥ | -- | -- | 9 | ||||

| Elongation at break, % ≥ | -- | -- | 250 | ||||

| 8. Resitance to ozone ageing50pphm:20%,48h | Grade2 | Grade2 | Grade0 | ---- | |||

| 9. Adhesion of rubber to metal | With contact section in elastomer | ---- | |||||

| 10. Expansion rate in volume, % ≥ | ------ | 150 | |||||

| 11.Repeared water immersion test | Hardness (shore) | ___________ | 3 | ||||

| Tensile strength,Mpa ≥ | 350 | ||||||

| Elongation at break, % ≥ | 150 | ||||||

| 12.Low temperature bending (-20ºC×2h) | ---- | No crack | |||||

Groupes de Produits : Série d'arrêt d'eau > Hydrophilic Stop

Premium Related Products

autres produits

Produits phares

Les volets imperméables de boue de parties de corps de camion imperméablesRoulements de pot de PTFE avec la bonne qualité à l'EquateurRoulements en caoutchouc à haute amortissement aux États-UnisRoulement en caoutchouc d'isolation de plomb de vente chaude en TurquieGarde en spirale en plastique pour tuyau hydrauliqueTuyau flexible en silicone extrudé en siliconeLe meilleur arrêt d'eau hydrophile de prix avec la diverse taille (fait en Chine)Waterstop de PVC de haute performance pour le joint concret (fabriqué en Chine)Bandes en caoutchouc de silicone de porte de four résistant à la chaleurRoulement sphérique ASTM standard en FranceTampon de roulement en caoutchouc pour la conception de ponts en PhilippinesWaterstop en caoutchouc de vente chaude pour la construction ingénierie matérielle imperméableBande de protection en caoutchouc EPDM pour portes de voitureBande de joint de porte en caoutchouc auto-adhésif de haute qualitéProfil réfrigéré composé de bande de joint de porte de conteneur de camion de porte de camion de personnalisation / PVCBande de joint en caoutchouc bon Flexible son rebord de fenêtre isolation